Anúncios

Global supply chain challenges overview

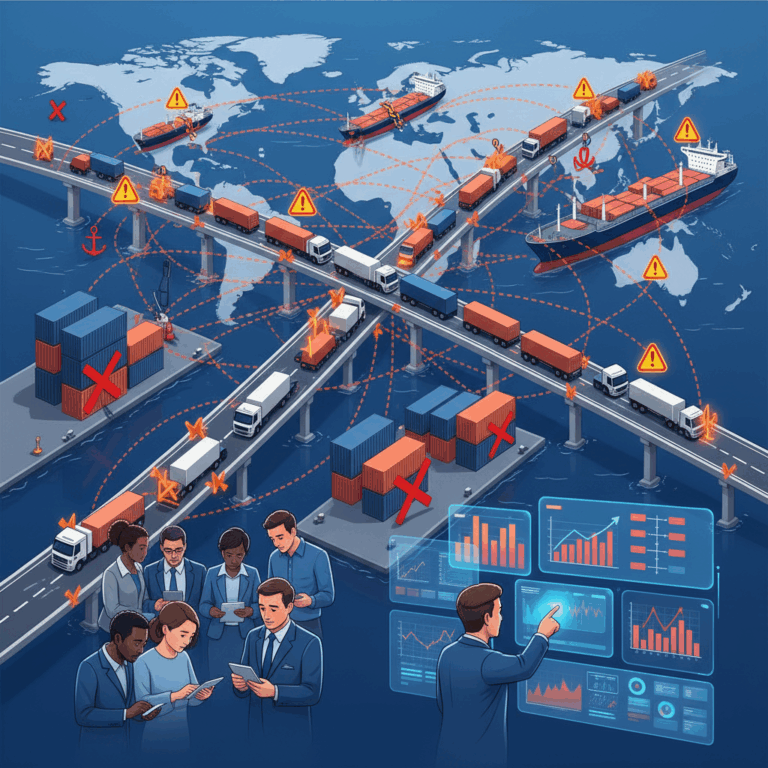

The global supply chain landscape has grown increasingly interconnected, exposing vulnerabilities that impact operations worldwide. Disruptions now arise from multiple layers of economic, geopolitical, and technological shifts.

From the pandemic’s disruptive effects to ongoing geopolitical tensions, companies must navigate a complex web of challenges. Understanding these is key to building more resilient supply networks in a volatile environment.

Anúncios

Economic and geopolitical factors

Economic uncertainty persists with fluctuating oil prices, inflation, and changing trade policies, creating unpredictable costs and operational difficulties. These economic dynamics directly impact supply chain efficiency.

Geopolitical tensions like tariffs, trade conflicts, and weakened multilateral cooperation continue to reshape trade routes. Firms face pressure to reconsider where and how they source materials to reduce risks.

Anúncios

The rise of economic statecraft and national security concerns drives reshoring and nearshoring trends. While these strategies improve responsiveness, they also involve significant expenses and talent shortages, complicating implementation.

Labor, sustainability, and technology gaps

Labor shortages remain widespread, often due to demographic changes and skill mismatches with emerging technologies. This gap hinders many industries from meeting operational demands effectively.

Increasing sustainability pressures require companies to comply with varied ESG regulations globally. Balancing these demands alongside competitiveness continues to challenge supply chain strategists.

The growing digital divide creates disparities between regions adopting advanced AI and automation and those lagging behind. This divide also increases cybersecurity risks and limits overall supply chain resilience.

Core disruptors affecting supply chains

Resource constraints and visibility issues

Resource shortages in areas like IT infrastructure, skilled labor, and capital restrict companies’ agility post-disruption. These constraints slow down recovery and scaling efforts in critical sectors.

Supply chains suffer from limited visibility, with opaque data and unreliable logistics making it difficult to predict or respond quickly to emerging disruptions. This lack of transparency undermines resilience.

Enhancing real-time tracking and data sharing is vital to overcome these hurdles and improve overall operational responsiveness, enabling better risk management across the supply network.

Digital divide and cybersecurity risks

The digital divide creates uneven adoption of vital technologies like AI and automation, causing chokepoints in less advanced regions. This disparity hinders seamless global supply chain integration.

Cybersecurity threats rise as digitization grows. Many organizations face increasing cyber risks that can lead to operational disruptions and data breaches, highlighting the need for robust security protocols.

Bridging the technology gap while strengthening cybersecurity measures is essential to safeguard supply chains and to enable effective digital transformation and resilience.

Trade policy and reshoring trends

Shifting trade policies, including new tariffs and restrictions, force companies to rethink sourcing and logistics strategies, often increasing complexity and costs within supply chains.

The reshoring and nearshoring trend grows as firms seek to reduce reliance on distant suppliers to mitigate risks and improve responsiveness. While beneficial, these approaches require significant upfront investment.

Balancing these strategies with cost efficiency and labor availability remains a central challenge for companies aiming for sustainable supply chain operations.

Recovery strategies for supply chain resilience

Building resilience in supply chains demands focused recovery strategies that address underlying vulnerabilities. Effective approaches combine technology, diversification, and workforce investment.

Companies must adopt innovations and foster collaboration while preparing for future uncertainties. These measures help transform disruption risks into opportunities for sustained growth.

Technology adoption and innovation

Advanced technologies like AI and predictive analytics improve demand forecasting and risk management, enabling companies to act before disruptions escalate. These tools enhance decision-making accuracy.

Automation and IoT increase operational efficiency by reducing dependence on manual processes, accelerating production, and improving real-time tracking. This increases supply chain agility.

Cloud computing and additive manufacturing support flexible production setups, allowing swift response to market changes. Cybersecurity investments are critical to protect these digital assets from growing threats.

Diversification and supplier collaboration

Spreading suppliers across multiple geographies mitigates risks of disruptions tied to single regions, lowering dependency on any one source. This strategy builds flexibility and enhances supply chain security.

Strong relationships with suppliers foster information sharing and resource pooling, enabling quicker, coordinated responses to crises. Collaborative networks align incentives to manage risk collectively.

Government aid and financial support during disruptions can stabilize supply chains, especially when paired with diversified sourcing strategies. These efforts help smooth recovery phases and sustain operations.

Scenario planning and workforce development

Proactive scenario planning allows companies to anticipate various disruption types and prepare appropriate responses, reducing reactive crises management. Stress testing systems exposes vulnerabilities early.

Maintaining inventory buffers provides a safeguard against sudden shortages, though it involves balancing costs. This approach helps ensure continuity during supply interruptions or demand spikes.

Continuous workforce upskilling addresses skill mismatches and ensures talent aligns with evolving technologies. Investing in human capital strengthens organizational adaptability in a changing supply chain environment.

Future outlook and strategic priorities

As global supply chains evolve, organizations must prioritize balancing risk and flexibility to remain competitive. Integrating adaptive strategies will enable better response to unpredictable challenges.

Investing in human capital and cutting-edge technology also plays a crucial role. A skilled workforce combined with innovative tools drives supply chain resilience and long-term success.

Balancing risk and flexibility

Effective management requires balancing risk mitigation with operational flexibility. Companies that remain rigid may fail when disruptions occur, while too much flexibility can increase costs.

Developing agile supply networks allows firms to pivot quickly during crises without sacrificing efficiency. Scenario planning and diversified sourcing contribute to this adaptability.

By continuously evaluating risks and adjusting strategies, businesses can maintain continuity and capitalize on emerging market opportunities despite uncertainty.

Investing in human capital and technology

Skills development is essential, as labor gaps and evolving technologies demand continuous workforce upskilling. Training programs ensure employees meet new operational requirements.

Technology investments in AI, automation, and data analytics improve forecasting, efficiency, and risk management, creating smarter and more resilient supply chains.

Emerging trends in technology and talent

Integrating IoT and cloud computing fosters real-time data sharing and flexibility, while strategic hiring addresses talent shortages. Together, they build a future-ready supply chain ecosystem.

Firms that align human expertise with advanced technologies position themselves to respond rapidly to disruptions and maintain competitive advantage in a volatile landscape.